AdvanSix Partners with Balboa Inspection and Maintenance for the Robotic Inspection of Cooling Water Header Pipe System

By: Tory Tingen of AdvanSix and Brian Carlson of Balboa Inspection and Maintenance

In early 2020, AdvanSix Inc., and more specifically its Hopewell plant, began approaching various pipeline inspection service providers to determine the feasibility of conducting an in-line inspection (ILI) on the piping for a cooling water system. This Unpiggable section of pipe was installed in the mid 1970’s. The piping system had never been thoroughly inspected, which in many ways was due to the fact that, until now, the only option for a full inspection was to excavate the entire system. The system had limited to no access and numerous offtakes. The system also contained various diameters, ranging from 18 to 30 inches. In addition to being below grade, AdvanSix would also have to get through a concrete slab to gain access. Although there are no requirements to inspect this piping system, AdvanSix took a proactive approach to ensure any future leaks could be stopped before they start. After considering numerous ILI vendors, AdvanSix selected Balboa Inspection and Maintenance to perform the inspection.

Job Preparation:

Prior to contract award Balboa personnel visited the AdvanSix facility and conducted a site walk with AdvanSix Engineers. In addition to the site walk, Balboa Engineering reviewed the system drawings and created 3D renderings of the piping system, including renderings of where the bell holes would need to be placed. These renderings provide a clean, easy to visualize picture of the system for AdvanSix Operations and Management, allowing them to easily determine the preparation work that would need to be conducted. Upon contract award, Balboa and AdvanSix worked together to ensure all preparations were happening on schedule and that the inspection would go off without a hitch.

Technology Selection

The MOCCASIN In-Line Inspection Crawler was selected for this job. This tool would be able to cover all pipe diameters and could be launched without overhead lifting. It would also lend itself to being launched in very confined spaces. The MOCCASIN would also be able to accommodate up to 1.25 inches of internal contaminants including tuberculation, which is relatively common, even with treated water lines.

The MOCCASIN

The MOCCASIN can inspect pipe diameters from 16 to 54 inches. It has a maximum travel distance of 1,600 feet and can navigate 1.5 diameter bends. It is also capable of diameter changes of up to 8 inches, i.e. the tool can travel from 16 to 24 inches. It can inspect up to 3,000 feet in a 12-hour shift. The MOCCASIN ILI system utilizes the Alternating Current Field Measurement (ACFM) technique for the detection of metal loss in the pipe wall. Prior to inspection start, a frequency is generated in the pipe wall by fastening a cable to the beginning and end of the run that is to be inspected. When the frequency generator is turned on fields are generated in the pipe. When an anomaly is present, changes in the electrical conductivity and magnetic permeability of the pipe occur. The MOCCASIN ILI crawler navigates the pipe utilizing cameras and on-board sensors to detect these field changes. The results are processed in real time and a wall loss calculation is completed.

The MOCCASIN Robotic ILI Pipe Crawler

Robotic Control system for the MOCCASIN ILI Crawler

Inspection:

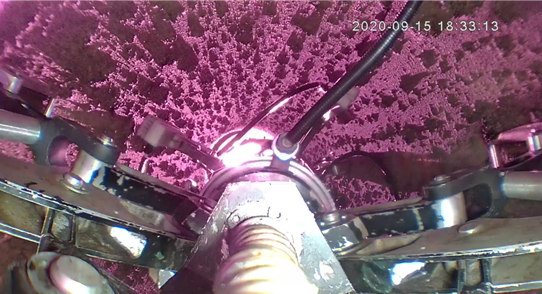

The AdvanSix inspection commenced on September 15, 2020 at 7AM. Prior to the start of the inspection, the AdvanSix team cut through a small section of concrete. Once the concrete was removed, a vacuum excavation truck was utilized to remove the soil around the header endcaps. The soil for this bell hole was comprised mostly of sand with high water content. As a result, every square inch of the bell hole had to be shored to prevent ingress, which also lead to the presence of numerous hydraulic shoring jacks around the launch point. After the excavation, the endcaps for the two 30-inch headers were removed. To launch the MOCCASIN, the tool was broken down into three sections and hand carried to the pipe entry point. The tool was then re-assembled in the pipe opening, powered on, and the inspection commenced. Almost immediately after the inspection began the MOCCASIN encountered tubercules in the pipe. They were 20 to 25 millimeters high and were evenly spread across the surface, averaging 1-3 tubercles for every 6-inch square. Fortunately, the MOCCASIN was designed to accommodate the larger standoff and the inspection continued without incident.

Results:

Balboa adhered to the allocated plant outage schedule and successfully completed the inspection within approximately 8 hours. The inspection identified three potential anomalies which were analyzed and evaluated within 3 days of the inspection. These anomalies were within an acceptable range for deferment and will be verified and repaired, if necessary, during the next outage. With the pipeline integrity and safety validated, AdvanSix was able to put the pipeline back into service.